Standard operating parameters:

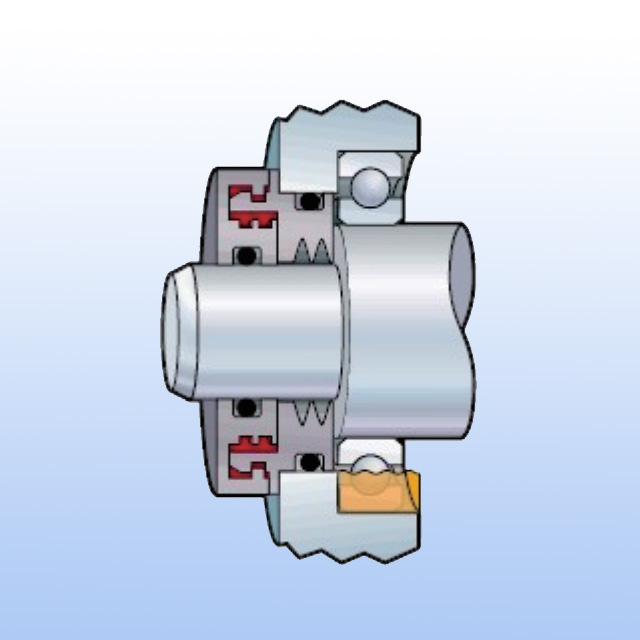

Runout: 0.25 mm

Linear speed: 25m/s

Pressure: 0.35bar

Temperature range: -40 to 120°C

Movement amount: ±0.08mm

Shaft/Hole Tolerance: ±0.05 mm

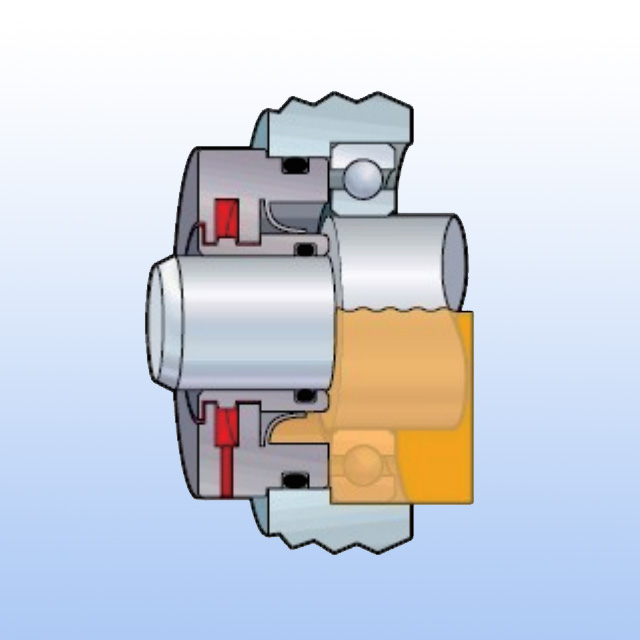

Special designs available

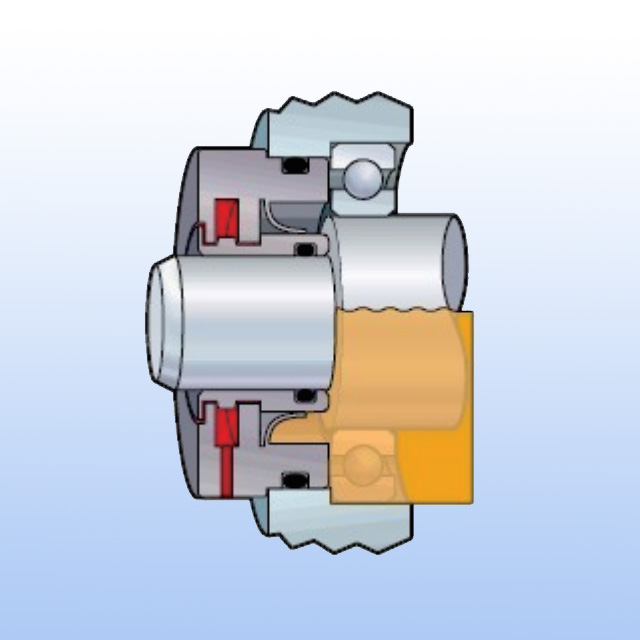

Sealing material:

Standard: Special teflon and stainless steel ring

Optional: Food Grade PTFE and Stainless Steel Rings, Antimicrobial PTFE and Stainless Steel Rings, FDA 3A PTFE and Stainless Steel Rings

O-ring material:

Standard: Fluorine rubber

Optional: Nitrile rubber, FDA silicone rubber, ethylene propylene rubber, Aflas® fluoroelastomer

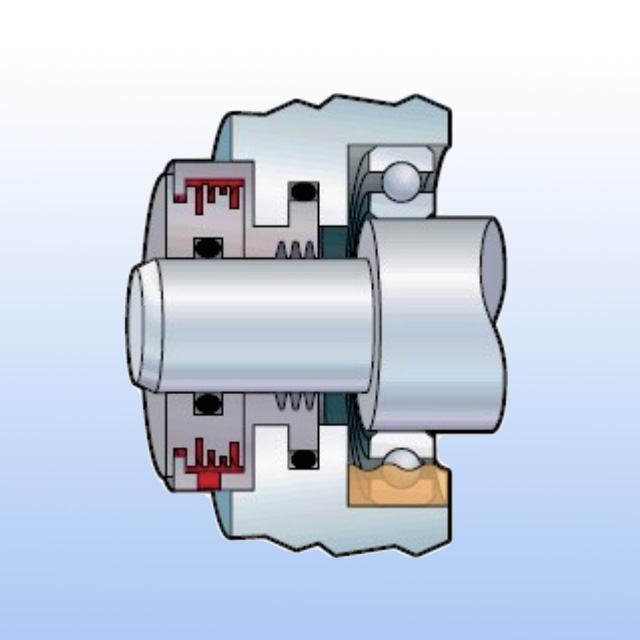

Maintenance: Grease, splash oil, oil mist, or oil immersion.

Exclusion: Exclude a large amount of water mist and dry dust contamination in the bearing cavity.

Equipment: It is most suitable for the equipment that needs to be washed frequently and needs to be lubricated in the food processing industry. For gearboxes, motors, pumps, mixers, cooling towers, wastewater treatment aerators and custom equipment that require lube submersion or large oil splashes.